Caterpillar released many variations of the 3406 before finishing on the 3406E. This included the 3406A, 3406B, 3406C, and finally the 3406E. The 3406A/3406B were both fully mechanical engines. The C model first began to see electronic functions with its fuel pump, but remained mostly mechanical. Finally, they produced 3406E, being the first fully electronic motor that worked well.

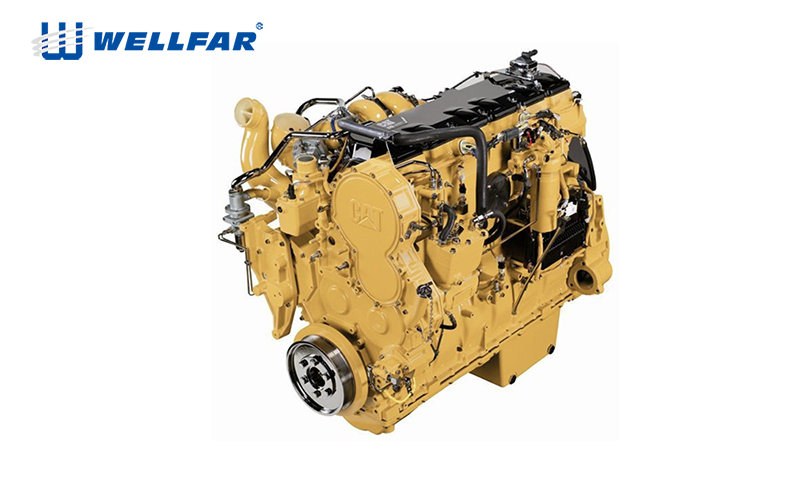

Figure 1 3406E engine

One of the common problems of 3406E is oil leaks. A common spot for leaks is near the rear side of the engine around the spacer plate and the cylinder block. During the production of the 3406E, Caterpillar wasn't using the best gaskets. In later models this was fixed, but it remained an issue throughout the early production of these engines. Another cause of these oil leaks is hardened rubber plugs near the back of the engine block due to aging.

Figure 2 oil leakage form rear side of spacer plate

Caterpillar released the C15 in 1999 following the production of the 3406E. This engine is very popular because of its reliability and versatility. It's so versatile in fact, that Cat lists over 34 applications that are powered by this engine. These include combines, harvesters, paving equipment, pumps, earth-moving equipment, aircraft support, and many more.

Figure 3 C15 engine

This design was meant to improve on the previous 3406E model. These improvements included gasket upgrades and better seals to fix those leaks we mentioned before.

In an effort to improve upon the 3406E diesel engine, Caterpillar introduced relief slots on the cylinder head to prevent pressure on the gaskets. Unfortunately, after the addition of these slots, the gaskets were known to fail a bit more often.

The Caterpillar C15 shifted over to the C15 ACERT in 2004. The term ACERT is an abbreviation for Advance Combustion Emission Reduction Technology. This engine mainly focused on the air and fuel systems in an effort to meet the strict EPA emission requirements set in 2002.