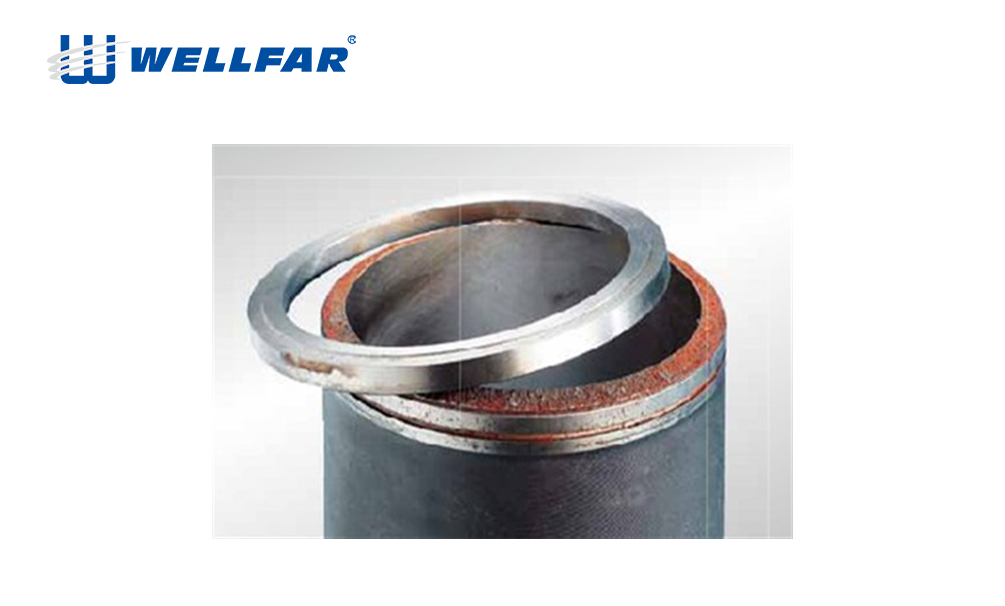

1. Cylinder liner flange broken

Cylinder liner on which the flange had been torn off completely, which is arguably the most common failure on both dry and wet cylinder liners in modern diesel engines.

Figure 1 Cylinder liner flange broken

Figure 2 Cylinder liner flange broken

Possible cause:

1. careless handling before installation

2. improper installation procedures

3. poor surface preparation

other causes includes:

1. Worn liner flange seating surfaces on the engine after an extended running period.

2. Dirty or corroded liner flange seating surfaces.

3. Failure to ensure that the flange seat is perfectly rectangular and/or parallel.

1. Incorrect cylinder head gaskets.

2. Non-compliance with the engine manufacturer's prescribed tightening torques and tightening angles when installing the cylinder head.

3. Wrong number of sealing rings.

4. Sealing rings jammed underneath the liner flange.

5. Use of incorrectly dimensioned gaskets.

6. Use of liquid sealants.

7. In the case of dry press fit cylinder liners: installation fault through excessively high press-in force.

8. Prescribed liner protrusion incorrect.

- Reworking of the liner seat without due care for the proper form

2. Cavitation issues

Figure 3 left shows a view of a cylinder liner that appears to have been perforated by corrosion, right shows a close-up view of what appears to be the progress of rust/corrosion through the wall of the same cylinder liner

Cavitation occurs as the result of several factors that combine to induce high-frequency vibrations in the wall of the cylinder liner. This typically occurs where the liner's wall is subjected to the lowest bearing pressure from the piston as it moves between TDC and BDC and in a perfect engine, these vibrations would be damped out or absorbed by either the crankcase or the cylinder head(s).

Causes of cavitation

1. Coolant temperature too high.

2. Coolant pressure too low.

3. Coolant boiling point too low.

4. Combination of the above.

5. Failure to comply with the correct piston clearance, e.g. re-installation of pistons that have already been used, or use of cylinders manufactured too large.

6. Irregularity in liner flange seating surface – poor or inaccurate seating of the cylinder liner in the housing (refer to the chapter entitled "Torn-off flange on the cylinder liner").

7. The required permanent anti-freeze protection with corrosion protection or corresponding additives in the coolant are missing.

8. Unsuitable coolants such as salt water (sea water), aggressive or acidic water or other liquids.

9. Insufficient pre-pressure in the cooling system.

10. Incorrect sealing rings and/or sealing compound or silicone on the liner flange.

11. Incorrect number of sealing rings.

12. Engine operating temperature too low

13. Installation of additional sealing rings in the undercut on the liner

Figure 4 - liner installation structure 01 Liner protrusion 02 Tombak shim 03 Undercut 04 O-ring

Other failures includes:

Lower side of liner scuffing

Possible cause is liner O-rings that twisted during installatioin